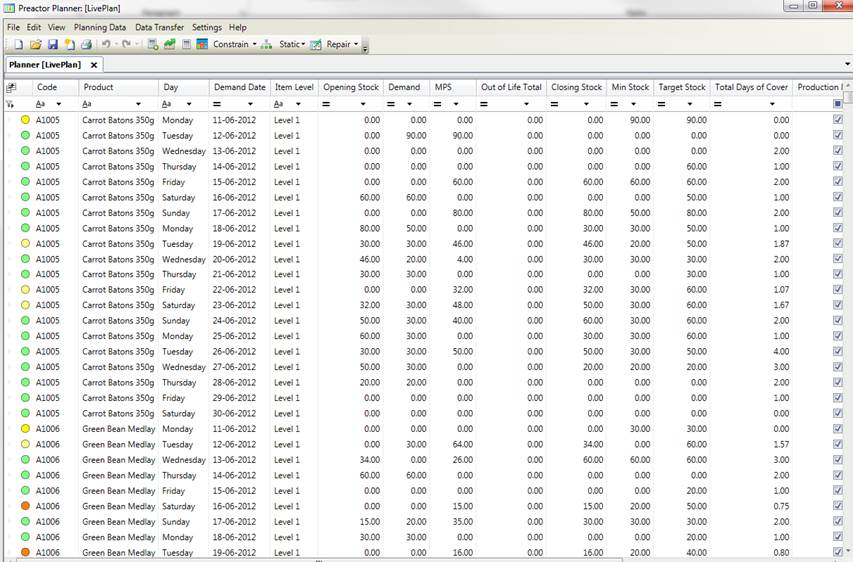

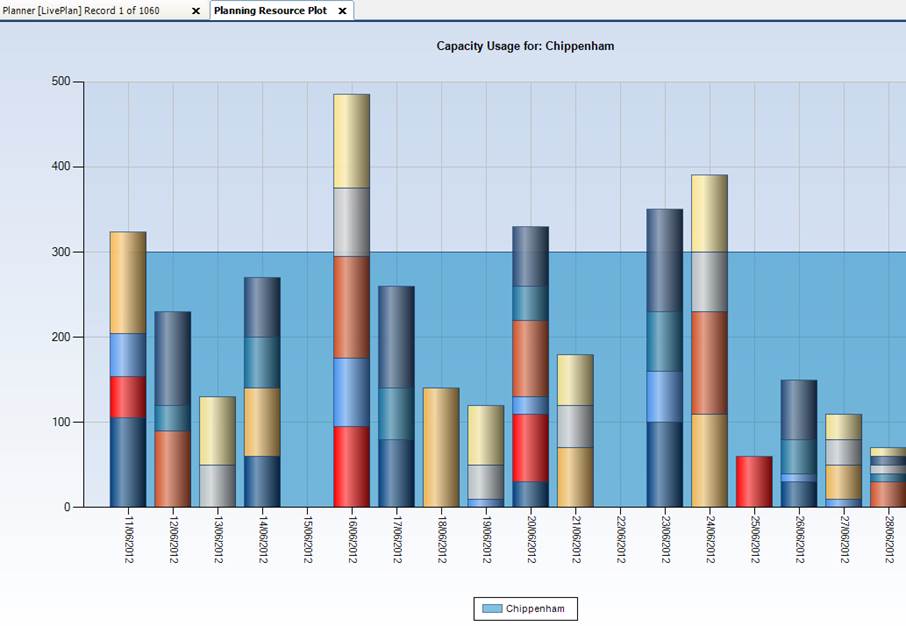

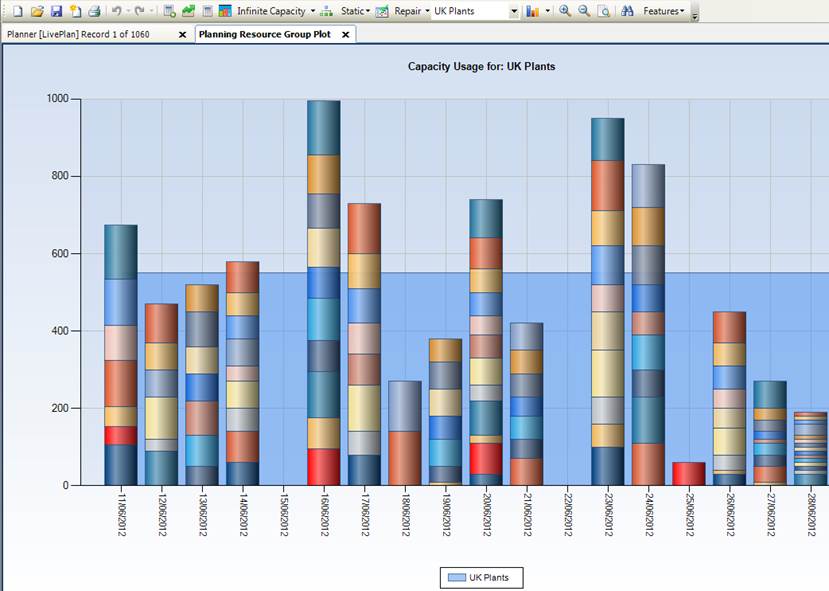

Planning can be executed in finite or infinite capacity mode and planning time periods can be days, weeks, months or a combination of all three.

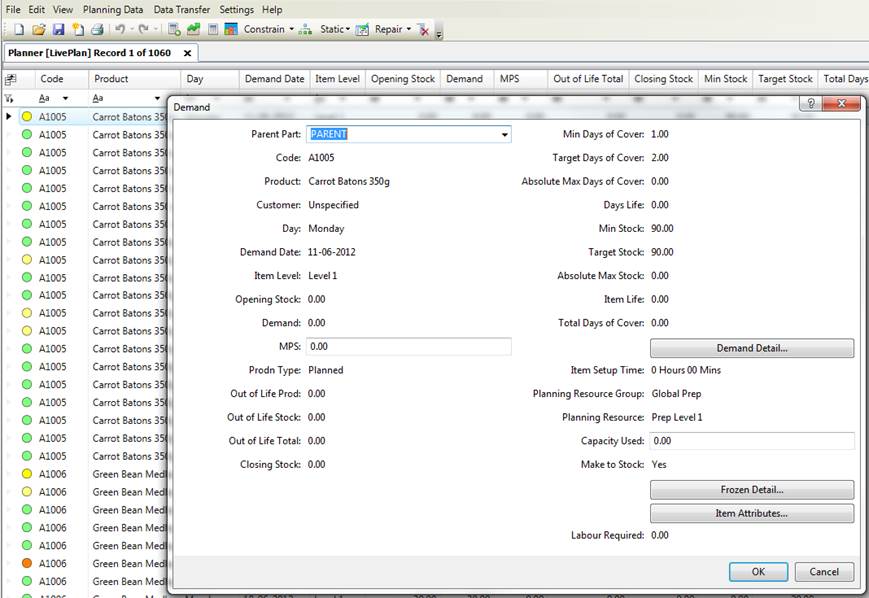

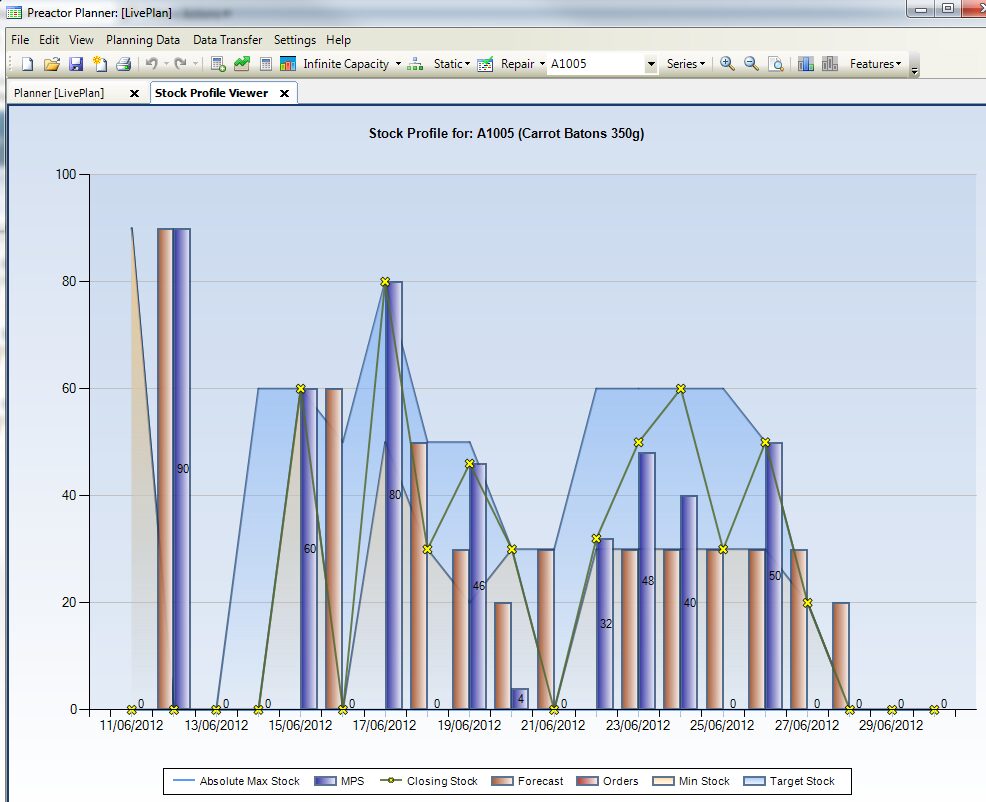

By using Opcenter Planning, parameters can be set against each item code, which allows different calculations for each item. For example, some products may be in “Make to Stock” mode while others are in “Make to Order” mode.

If used together with a Opcenter Scheduling system, detailed production schedule information can be sent back to planning system and this will override planned volume with scheduled volume. The Master Production Schedule (MPS) can then be recalculated using the production schedule as the base for the new results.